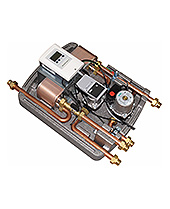

ModvFresh 4

Pump unit to deliver fresh hot domestic water (HDW) with electronic control. High efficiency pump and control of return temperature of primary loop. Thermostat function.

| Employment: on the inertial cylinders or similar, connected to solar thermal installations, wood, pellets, biomass boilers etc. It provides fresh hot domestic water, avoiding phenomena of bacterial pollution, such as the legionnaire’s disease etc., made by the stagnation of the hot water. |

Control and management of the integration source of the water tank in order to maintain the water temperature at the lowest necessary level. Optimization of control of return temperature to storage tank thanks to the control for diverting valve (the valve is optional).

This unit, by a special electronic controller, modulates the speed of the primary circulating pump, from a minimum speed of 10% up to 100%, in order to provide always a precise temperature of the exploitation of the water (f.i. 45°C). The variation of the requested flow is suddenly recorded by a digital sensor that gives the inputs of the flow and the temperature to the electronic controller, modulating the speed of the circulating pump accordingly.

This unit, by a special electronic controller, modulates the speed of the primary circulating pump, from a minimum speed of 10% up to 100%, in order to provide always a precise temperature of the exploitation of the water (f.i. 45°C). The variation of the requested flow is suddenly recorded by a digital sensor that gives the inputs of the flow and the temperature to the electronic controller, modulating the speed of the circulating pump accordingly.

- Up to 100 kW, with variable flow from 2 up 40 l/min, fully assembled and prewired,

- High efficiency circulating pump and control of return temperature of primary loop by a diverting valve (optional);

- Function of thermostat integration of the storage tank: it activates the energy source in case water temperature of the storage tank does not comply with set up timetables;

- External sensor boxes to connect easily external sensors and relays.

- Delivered water temperature: 45°C with a supply water temperature of 10°C. Consequently the power is about 98 kW at the flow of 40 l/min. Anyway the temperature of the HDW is adjustable every single degree up to 70°C;

- The minimum requested inlet temperature to the heat exchanger is 60°C in order to guarantee the declared performaces to the maximum flow (with 35 K thermal ∆t);

- A big surface heat exchanger weld-braised plate made in stainless steel AISI 316 guarantees a remarkable thermal exchange that allows a water return to the puffer with a temperature until 20°C. This favours a perfect heatig power from the solar or heating pump contribution;

- Available with our without recycling circulating pump (funcionning “on request” or “by time bands”; adjustable temperature until 40°C);

- The heat exchanger can be easily removed in case of maintenance and/of cleaning;

- A digital sensor allows an accurate power recording (total, yearly, monthly, weekly and daily);

- PPE insulation box (398 x 500 x 207 mm). A special back plate fixes the unit to the insulation box and it allows a quick fitting to the wall or to the solar cylinder;

- The pump unit is supplied with 3/4” Male connections (pipe-union).

FIELD OF UTILIZATION:

For a maximum power of 100 kW and flow up to 40 l/min.

Nominal supply temperature of the storage tank: 60°C.

Nominal temperature of the water supply: 10°C.

Nominal temperature of HDW production: 45°C, adjustable from 30°C to 70°C.

Recycling line temperature adjustable from 10°C up to 40°C.

For a maximum power of 100 kW and flow up to 40 l/min.

Nominal supply temperature of the storage tank: 60°C.

Nominal temperature of the water supply: 10°C.

Nominal temperature of HDW production: 45°C, adjustable from 30°C to 70°C.

Recycling line temperature adjustable from 10°C up to 40°C.

ModvFresh 4 different hydraulic schemes

Preset schemes of ModuFresh 4 controller can be easily and flexibly enriched by two additional functions: additional heating with thermostat function and/or control of return temperature to storage tank thanks to a diverting valve (optional). To make it easy, hereafter schemes show the type with active recycling, however it is also possible to configurate them without recycling.

(*) Please note: in scheme 5, the controller considers 25°C as fixed temperature inside the storage tank to manage diverting. In case you would need to read temperature and process the value in the controllers, it is necessary to order separately a TT/S2 sensor and to wire it to sensor box.

Diagrams of the pump unit performances

The following diagrams relate the user’s flow rate and the supply temperature to the buffer storage tank, according to the requested temperature of HDW. This allows to identify the minimum supply temperature needed to supply HDW at a required temperature and flow. Vice versa it is also possible to fix which is the maximum usable flow at the selected HDW temperature, at the available supply temperature.

Delivery of HDW

|

Delivery of HDW with reclycling

|

|

Preset schemes of ModuFresh 4 controller can be easily and flexibly enriched by two additional functions: additional heating with thermostat function and/or control of return temperature to storage tank thanks to a diverting valve (optional). To make it easy, hereafter schemes show the type with active recycling, however it is also possible to configurate them without recycling.

elivery of HDW with reclycling and

additional thermostat function |

Delivery of HDW with reclycling and

control of return temperature |

additional thermostat function and control of return temperature (*) |

(*) Please note: in scheme 5, the controller considers 25°C as fixed temperature inside the storage tank to manage diverting. In case you would need to read temperature and process the value in the controllers, it is necessary to order separately a TT/S2 sensor and to wire it to sensor box.

Relay box

|

Sensor box

For a fast and easy connection of the temperature sensors, vannes or circulating pumps you do not have to handle the controller, it is enough to plug the cables in the automatic connectors of the sensor box. |

|

|

Technical Features

Minimum diameter size of the pipes: DN20 (Cu 22x1); DN15 for the recycling line |

Pump unit assembled with optional ball valves kit

|

|

Diagrams of the pump unit performances

HDW pump unit ModvFresh - 100 kW

La temperatura nel puffer deve essere superiore di almeno 5 K rispetto a quella desiderata per l’acqua sanitaria. Differenziali di temperatura maggiori consentono di prolungare il tempo di spillamento.

|

Login

Login

Εγγραφή νέου μέλους

Εγγραφή νέου μέλους